Mechanical Gear Reducer Design

Engineering project on dimensioning, modeling, and validating a 4:1 industrial gear reducer designed to transmit 7kW of power continuously over 22,000 hours.

Engineering project on dimensioning, modeling, and validating a 4:1 industrial gear reducer designed to transmit 7kW of power continuously over 22,000 hours.

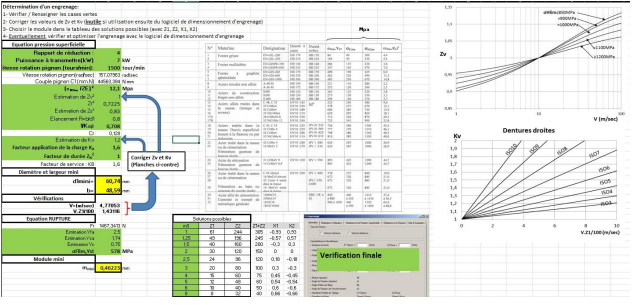

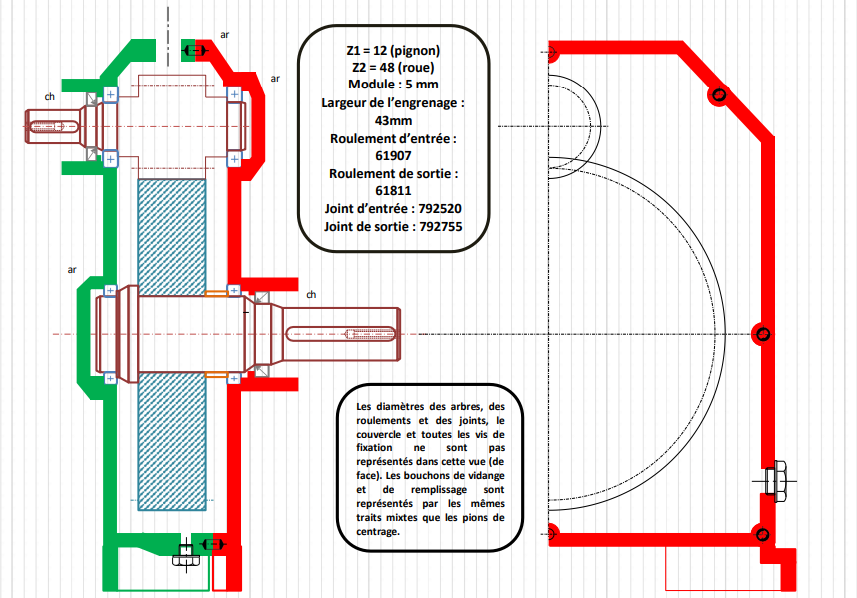

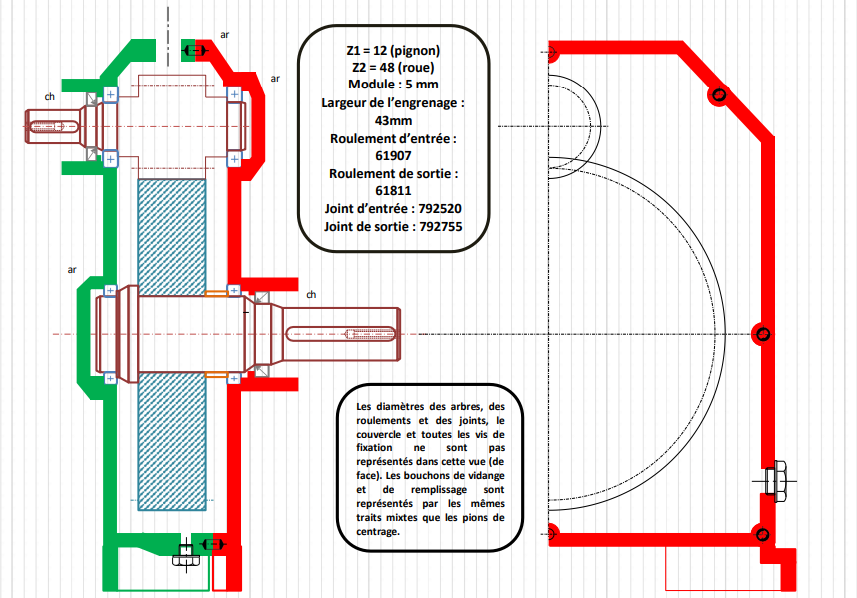

Preliminary design study carried out at Arts et Métiers (ENSAM), focused on the early-stage conception of a parallel-axis industrial gearbox designed to transmit 7 kW with a reduction ratio of 4:1. with an input speed of 1500 rpm. The goal was to evaluate technical feasibility, define the general architecture, and perform the preliminary sizing of the main mechanical components.

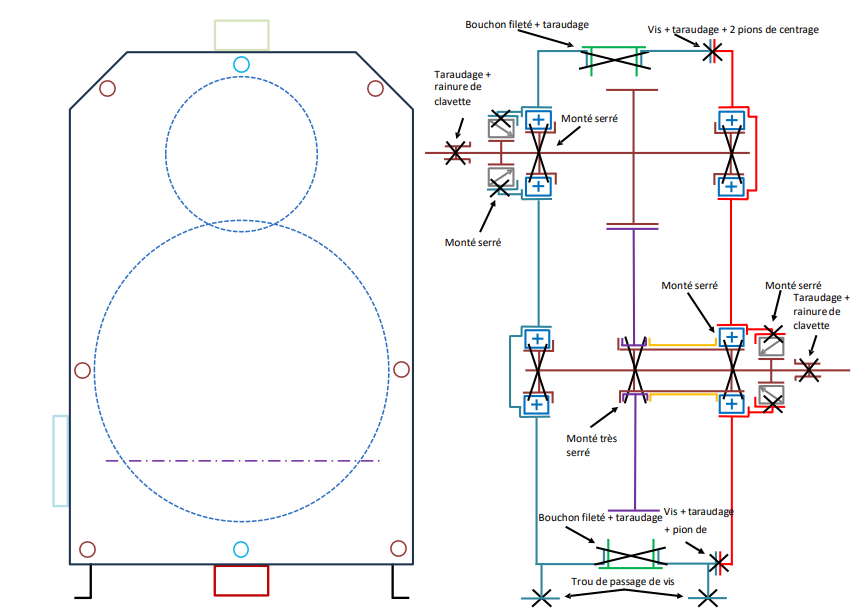

The study covered functional definition, benchmarking of existing solutions, analysis of the mechanical architecture ("en chape" configuration to limit shaft deflection), as well as the preliminary sizing of the gear set, shafts, keys, bearings, and seals. Lubricant selection and thermal evaluation were also carried out.

Oil bath lubrication verified using the Shell method (speed limits met). The viscosity determined by the speed-based approach resulted in an oil temperature of approximately 95 °C. The selected oil is MACOMA R71, suitable for enclosed gear systems.

This preliminary study confirmed the system's technical feasibility and identified trade-offs between cost, durability, and compactness. The next steps will focus on full 3D modeling, tolerance calculations, and detailed thermal analysis.

View Report PDF